Ask DAN: What Do I Need to Know About Scuba Cylinder Safety?

Shutterstock.com/taro911 PhotographerLearning about cylinder safety can save a life.

Every year, scuba cylinder ruptures destroy property and injure or even kill fill-station operators as well as bystanders. Awareness, education and prudent actions by all who handle cylinders are crucial for preventing accidents.

Cylinder Safety Standards

Governing bodies, including the U.S. Department of Transportation, require that cylinders be designed, manufactured, inspected and certified to exacting engineering standards that provide safety margins to ensure decades of safe service for cylinders used according to the intended conditions.

The user must fill only to the rated service pressure and have cylinders inspected by qualified technicians. More than 90 percent of ruptures occur during filling, so diligent inspection is critical.

Related Reading: Ask DAN: How Do You Treat Decompression Sickness?

Why Cylinders Rupture

Factors that contribute to cylinder rupture include overfilling, physical abuse and inadequate inspection. Regular overfilling (i.e., exceeding the hydrostatic test pressure) will eventually cause deformation and an inability to withstand even the allowable working pressure.

Exposing overfilled cylinders to high levels of heat—such as in the trunk of a car—significantly increases the internal pressure. Aluminum cylinders are particularly susceptible to metallurgical changes when exposed to temperatures greater than 140 degrees over time, which can result in structural damage to the metal.

Internal cylinder corrosion combined with a lack of mandatory internal visual inspections can eventually lead to inadequate wall thickness and rupture. Cylinders that are not suitably clean or fitted with inappropriate valves and filled with oxygen-enriched breathing gas can explode due to internal fire.

It is important to note that even with dirty and inappropriate equipment, cylinders do not always fail. The technical specifications, however, indicate that fire is likely due to one of several ignition causes. Mechanical damage to the outside of the cylinder is easier to visualize. Damage due to the incorrect matching of cylinder and valve threaded connections is much harder to see and has caused several devastating accidents.

The average scuba cylinder contains more than 1 million foot-pounds force, which correlates to the kinetic energy of a 3-ton truck traveling at 70 mph. The potential release of this amount of energy in a cylinder rupture demands that users have a thorough understanding of how to safely handle a cylinder.

Related Reading: Top Techniques to Equalize Your Ears When Diving

Ensuring Cylinder Safety

A few easy steps can collectively reduce your risk of a cylinder-related incident. One key step is to get your cylinders inspected by reputable dive operators.

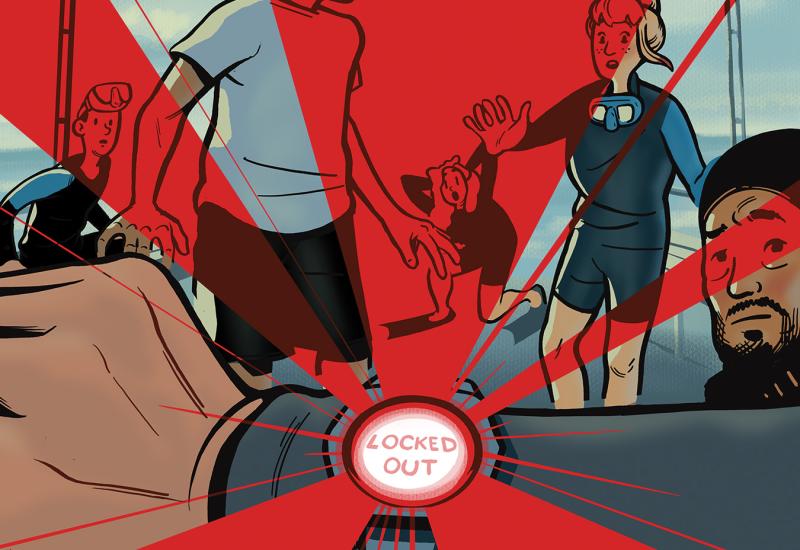

Courtesy Divers Alert NetworkA few easy steps can collectively reduce your risk of a cylinder-related incident.

At the end of each dive, purge cylinders after removing the regulator to prevent trapping moisture in the valve that can blow into the cylinder at the next fill.

To help the metal maintain its strength, store cylinders in a cool, dry place that prevents contact with any direct heat source. Store cylinders that will not be used for 90 days or longer almost empty—at around the first reading on the pressure gauge, which is typically between 100 and 200 psi (10 and 20 bar). Keep them upright in a secured position with the valve fully closed.

Examine cylinders for any signs of mechanical damage, such as dents or gouges, or evidence of valve damage caused by rough usage. Ruptures rarely occur from cylinders being dropped or knocked over, but valve damage is often the cause of injuries or fatalities.

Do not use a cylinder if you observe any corrosion or noticeable mechanical damage, you have reason to suspect inadequate or missing mandatory inspections, or the cylinder valve appears contaminated with any lubricant with an odor. If it is a rental, return it to the store; if it is yours, take it to a trained inspector regardless of the date on the visual inspection sticker.

Make sure you slowly and carefully open cylinder valves for oxygen or any nitrox mixture. A sticky valve warrants urgent attention.

Maintaining your cylinders as required and investigating any potential concerns you observe will add a level of safety. Add another level by having trained operators perform informal inspections during filling. A proper visual inspection and requalification by formally trained inspectors add a final level of safety. Accidents are the accumulation of many failures; safety is the accumulation of many layers of diligence.