Can Coral Reefs be Mass Produced? This Company Says ‘Yes.’

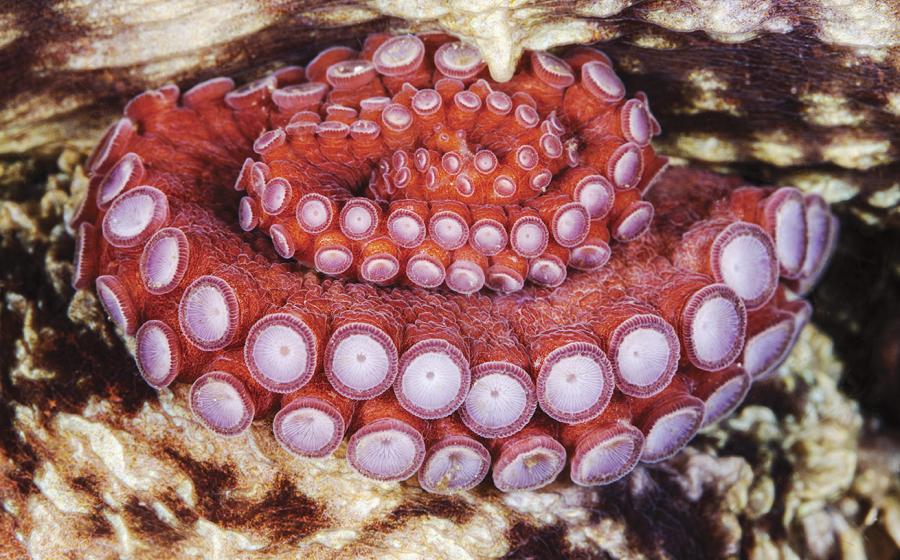

Courtesy Coral MakerCoral Maker says a single factory could produce 1 million skeletons per year using its 3D printing method.

Global coral reefs won’t disappear by 2100 if Coral Maker has anything to say about it.

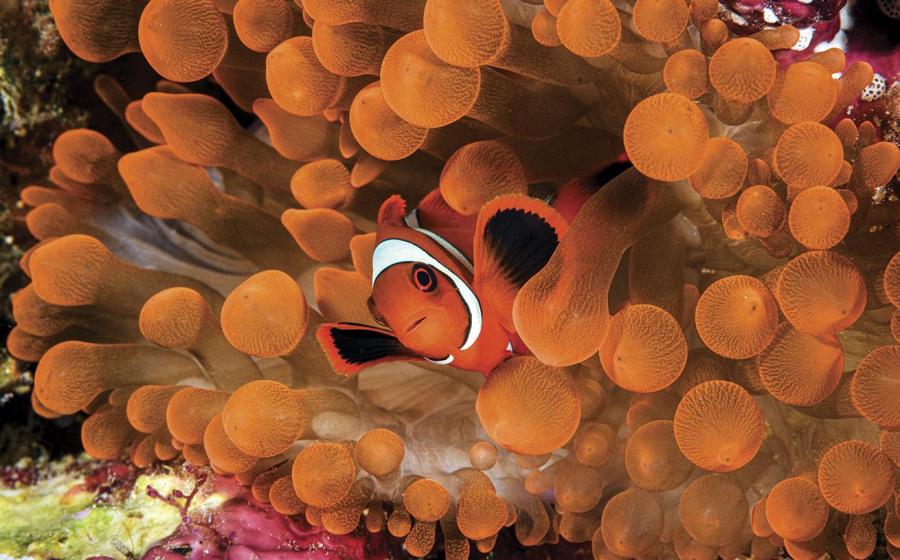

The organization, led by researchers at the California Academy of Sciences and manufacturing technology experts from Autodesk, has engineered simple domes with holes for coral plugs. These domes can be mass produced via dry casting or 3-D printing, after which live corals are grafted into the indents with robotic arms.

“In locations where automation is not feasible, the manual seeding process will be far quicker and more user-friendly [than current methods], with the seeds designed to click into place in the manufactured skeleton” and a base designed for “rapid attachment to the reef,” according to Coral Maker’s website. Both options “create a more user-friendly and streamlined product and process, [with] the potential to increase production of corals by orders of magnitude.”

Courtesy Coral MakerThe dome, riddled with notches to house coral plugs, is designed to easily attach to reefs during outplanting.

Magnitude is the name of the game. The first organization to mass produce 3D-printed coral skeletons, the group hopes to catalyze restoration at a scale that will outmatch predicted coral loss. Coral outplanting does not touch the primary driver of coral decimation—climate change—but research indicates corals would continue to disappear even if global warming leveled off today, creating continued space for restoration work.

Coral Maker currently produces 25,000 skeletons a year, but the organization says a single factory could produce 1 million skeletons per year using the method. COVID-19 shutdowns interrupted the work, but researchers continued producing the domes with at-home 3D printers to keep the project running on time, according to CNET.

It’s a process more streamlined than most coral regeneration efforts, like coral gardening, which take additional manpower and time from coastal communities.

"Coral reef restoration programs often operate with limited means," Shubham Goel, a Coral Maker team lead and a senior engineer manager at Autodesk, [tells CNET.](Global coral reefs won’t disappear by 2100 if Coral Maker has anything to say about it. The team, led by researchers at the California Academy of Sciences and manufacturing technology experts from Autodesk, has engineered simple domes with holes for coral plugs. These domes can be mass produced via dry casting or 3-D printing, after which live corals are grafted into the indents with robotic arms.) "We care deeply about simplicity and efficiency in every aspect of the design process."

The Coral Maker skeleton itself also contributes to the rapid maturation of newly planted coral colonies. By providing the coral with a skeleton, it doesn’t have to take the time to calcify its own structure. Instead, it can coat the existing skeleton and grow outward from there.

Naturally, corals take about three to 10 years to reach adult size. But with a premade skeleton, it may take only six to 18 months.

Coral Maker plans to deploy seeded prototypes into the ocean by the end of 2020, monitoring the impact and tweaking the design accordingly.

"If action is not taken now, the corals won't be there for the next generation," says Goel.