Eye on the Ball: Exploring the History of the Ball Watch Company

The Ball Watch Company is an American-founded watch manufacturer that originated in the 19th century. The company was instrumental in expanding the American railroad as its commitment to accurate, precise timekeeping greatly increased the safety and reliability of railway travel. The company’s continued pursuit of accuracy under adverse conditions has made their rugged, dependable watches a must-have tool for modern explorers.

For the uninitiated, Ball timepieces are easy to overlook; the Ball Watch Company name isn’t as instantly recognizable as iconic brands like Rolex, Omega or Blancpain and its prices are noticeably higher than most quartz and entry-level mechanical watches. Those in the know will tell you that the reverse is also true. While Ball watches aren’t quite as affordable as Seiko, Citizen or Luminox, they are an exceptional value when compared to the premium legacy brands, especially when one considers the historic legacy, high-quality performance and brilliant design they encapsulate.

History of Ball Watch Company

During the late 19th century, American railroad companies began to use standardized time zones. Previously, they relied on local time, which was determined in each individual municipality based on the relative position of the sun and could vary greatly between destinations. As the distance between destinations connected by railroads grew, so too did the variation in time of day. This made local time impractical and dangerous to use when calculating long-distance travel where trains would cross each other at different points of the line.

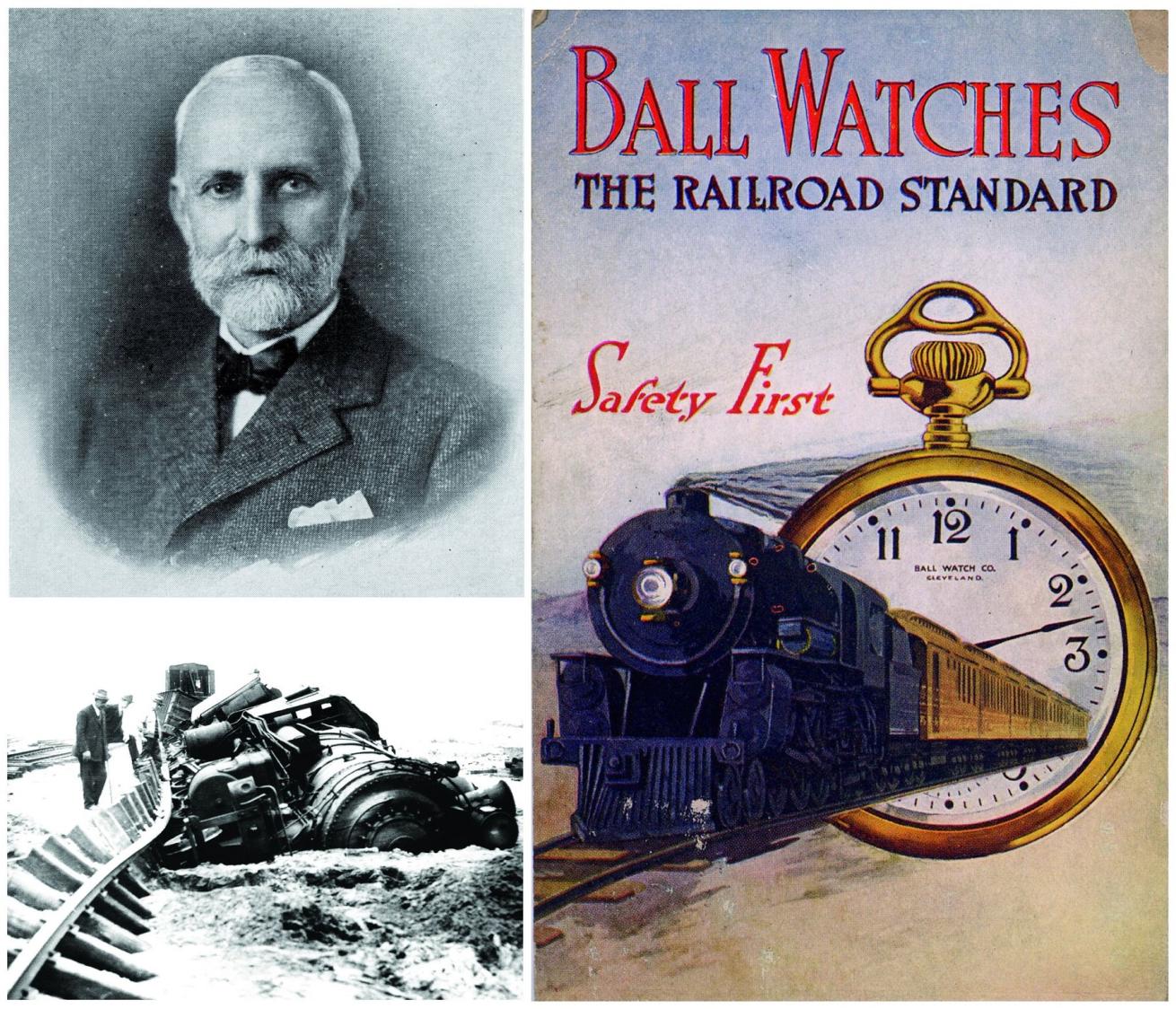

The adoption of standard time allowed for more effective, safe planning of railroad routes but executing them was still another matter. On April 18, 1891, a four-minute delay caused by a train conductor’s malfunctioning pocket watch resulted in a fatal head-on collision between two locomotives in Kipton, Ohio. In the aftermath, American railroad companies sought to provide their employees with more accurate watches to prevent future accidents. To that end, they appointed local renowned watchmaker Webster Clay Ball to investigate timekeeping conditions among the railroad lines and develop standards for watches used by railroad personnel.

Webb C. Ball was an Ohio-native who operated a watch repair shop in Cleveland, Ohio in the early 1880s and was one of the area’s major jewelry retailers. He was an early adopter of Standard Time. He utilized time signals, electrical signals sent via telegraph from the United States Naval Observatory, as a reference to determine the correct time of day, to bring accurate time to both his timepieces and Cleveland.

As Chief Time Inspector for the Lake Shore Railroad Company, Webb C. Ball subjected timepieces to an extremely strict criteria of design, accuracy and reliability. His rigorous system would later inspire the 1973 Swiss Society of Chronometry (COSC) Standard. It is also commonly attributed as the origin of the phrase “to be on the Ball” which is itself a reference to absolute precision and punctuality.

Webb C. Ball officially founded the Webb C. Ball Watch Company in 1894, which spread the use of watches bearing Ball’s railroad standard logo and further cemented the brand’s reputation for accuracy and reliability. The Ball Watch Company would become one of the largest wholesale distributors of railroad watches in the country, and even gained popularity outside the United States.

With the decline of the American railroad and the advent of cheaper battery-powered quartz watches around the 1960s, market forces threatened the sustainability of many mechanical watch manufacturers, Ball Watch among them. The company slowly ramped down production as consumers’ preferences shifted from traditional spring-powered mechanical watches to more affordable battery-powered timepieces.

Ball Watch would be revitalized in the early 2000s after the company relocated its international headquarters to Switzerland in La Chaux-de-Fonds, the historic seat of Swiss watchmaking. This change of scene provided Ball Watch with access to a wealth of highly skilled personnel and sophisticated materials. These materials included quality Swiss-made movements, which Webb C. Ball was known to use and modify in his own timepieces, but also additional materials like self-powered light tubes that had been developed during the following decades.

Technological Advancements

Reliability and accuracy were critical performance aspects of Webb C. Ball’s railroad timepieces. Today, Ball Watch Company continues to pursue its founder’s quest for precision and accuracy. As modern explorers push the edge of the unknown, whether traversing freezing Antarctic conditions, piloting planes at sonic speeds, summiting legendary peaks or, of course, plunging into the ocean’s depths, Ball Watch has developed instruments up to the task. As a result, the company holds over 30 patents and continues to raise the stakes with new innovations. Below are several standout features they’ve pioneered.

Always Visible Markers

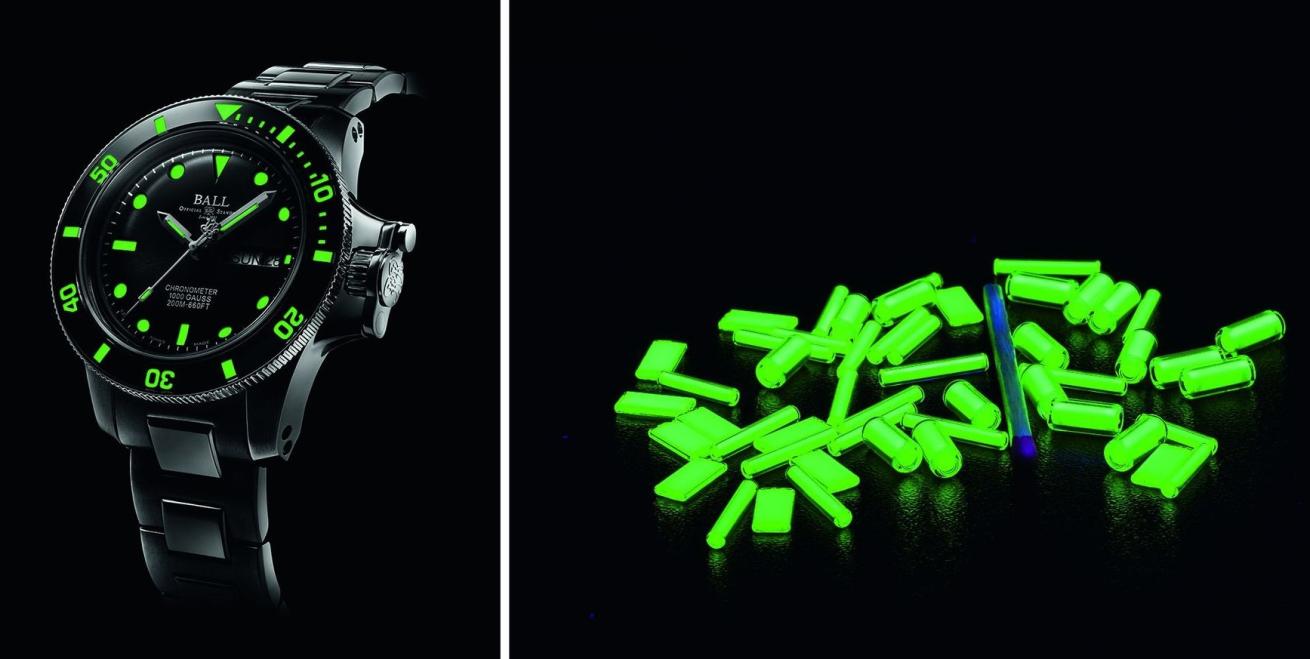

Most watches—and dive watches in particular—use luminous paint on the hands and makers so that they will glow and remain legible in the dark and at depth. Traditional luminous paint is “charged” by sunlight and artificial light, meaning it will eventually dim and darken over time without sufficient light exposure.

Ball Watch instead uses Swiss-made self-powered Micro Gas Tubes. These tiny hollow glass cylinders are filled with tritium gas and have an internal luminescent coating. The coating interacts with the electrons of the gas which produces light. This means it will glow constantly, no matter how much light exposure it’s had nor how long it has been in the dark. The emitted light is up to 100 times brighter than traditional luminous coatings and can be set in different colors. It will retain its original brilliance for up to 25 years.

Other watch brands have also adopted this method of creating “always visible” hands and markers. While their faces and hands may sport plentiful gas tube markers, the bezels usually have a limited number of markers. Some may even revert to luminous paint for the fine detail of the bezel’s indices. Ball Watch’s use of sapphire elapsed timing bezels elevate the whole undertaking with breath-taking beauty as the gas tubes are seamlessly hidden beneath the bezel’s surface to fully illuminate all the indices with the detail of a paint job and the brilliance of tritium.

Related Reading: Introducing ProTek's USMC Dive Watch Series

Shock and Awe

From the rattling of locomotives to the rough and tumble of an outboard dive boat, external shocks can impact mechanical watch components resulting in inaccurate time and even internal damage. That’s why quality, dependable timepieces need to be able to shrug off impacts without taking damage to their sensitive mechanical components.

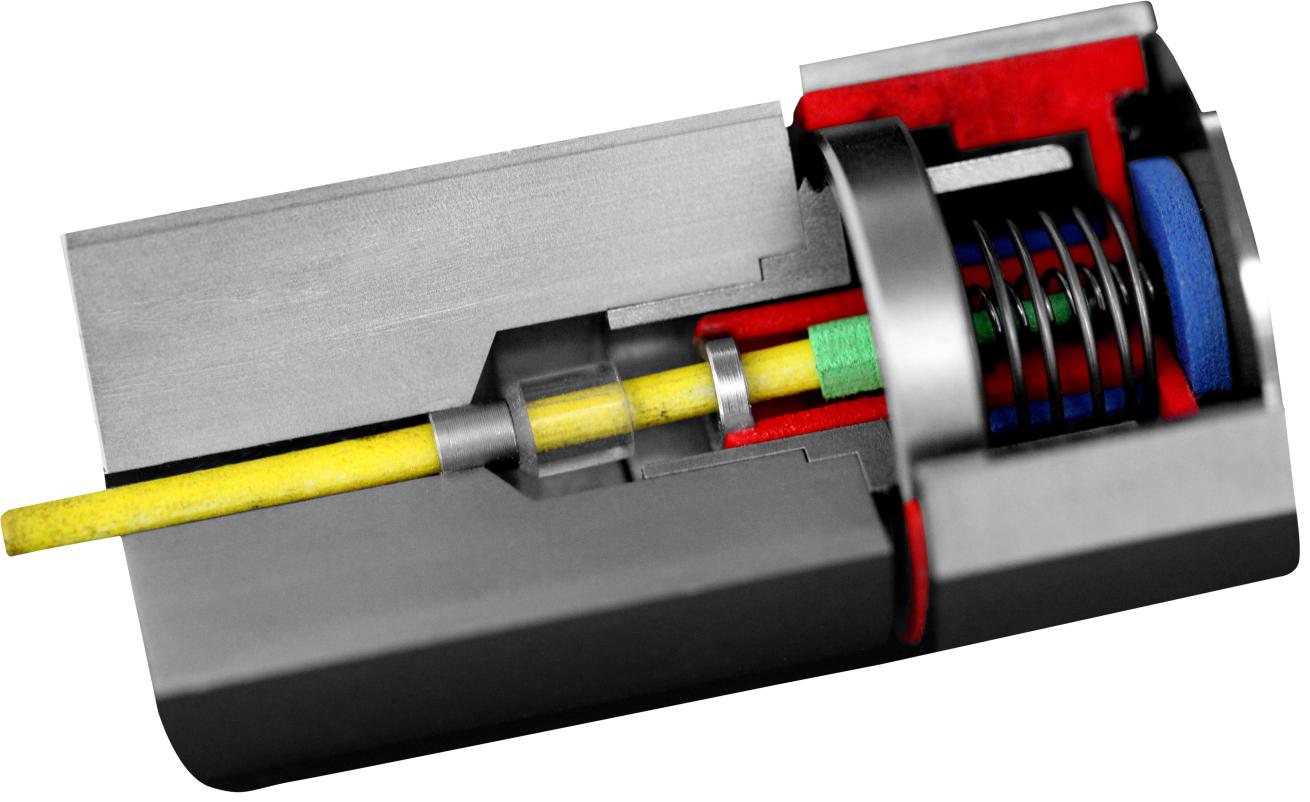

Every Ball Watch undergoes rigorous testing to verify shock resistance up to 5,000 Gs, and some models are tested to even higher standards. The balance spring is a small spring wound up in a concentric circle which is used to regulate a mechanical watch’s movement. It is vital for maintaining accuracy but is also incredibly fragile and particularly sensitive to sudden impacts.

Ball Watch’s patented SpringLOCK anti-shock system surrounds the balance system with a protective cage. The cage isolates the balance system by absorbing the energy of external impacts and limits the unfurling of the balance spring coils when the watch is subjected to shocks. The design reduces the effect of external impacts by 66 percent, ensuring that the watch maintains its accuracy when subjected to external shock impacts.

The Amortiser system is another anti-shock system developed by Ball that protects mechanical movement against external shocks. It consists of a protective and antimagnetic ring that runs around the mechanical movement which absorbs the energy created by side shocks. On some models, a rotor-locking system on the case back enables the user to lock and unlock the rotor's motion as desired. This prevents the impact energy from being transmitted to the movement, while the watch continues to run by drawing on its power reserve.

Crowning a Noble Gas

Helium, which is referred to as one of the Noble gases on the Periodic table due to its tendency not to participate in chemical reactions, is commonly associated with party balloons, but this same gas is also essential to deep sea divers. They use it to create specialized breathing gas that doesn’t induce the narcotic effect of nitrogen at depth and reduces the length of required decompression stops after lengthy deep-water dives — it also imparts the diver with a high-pitched chipmunk-like voice.

The atomic structure of helium is incredibly small. It can find its way out of, or into, the smallest leaks. This is especially true under pressure while diving or living in a pressurized diver habitat. While under pressure, helium can enter a dive watch and have no effect. But as the diver surfaces and returns to the ambient surface pressure, the Helium gas inside their watch expands and can’t exit the way it entered and increasing internal pressure will damage the watch.

To that end, dedicated helium escape valves have become a common feature on professional-grade dive watches geared toward deep underwater work. Ball Watch’s elegant, streamlined solution integrates an automatic helium escape valve directly into the crown of the watch. This design eliminates the damaging effects of helium expansion post-dive while preserving the watch’s classic aesthetic.

A Magnetic Personality

Magnetic fields can interfere with the accuracy of a watch’s movement. To guard against this, Ball Watch’s cases are built with non-magnetic corrosion-resistant ferritic stainless-steel materials and the interior of the watches have soft iron jackets and other protections around the movement. Ball watches are built to perform when exposed to magnetic fields up to 4,800 ampere per meter (A/m) without deviating more than 30 seconds a day.

Models equipped with Ball’s mu-metal shield have even more protection from anti-magnetic disturbances. Mu-metal is an alloy of nickel, iron, copper and molybdenum with very high magnetic permeability. It has the ability to attract and deviate static or low-frequency magnetic field lines and has anti-magnetic properties far superior to the soft iron usually employed in watchmaking. The use of mu-metal is a genuine industrial feat, capable of protecting a mechanical watch against magnetic fields up to an astonishing intensity of 80,000A/m and of defending it against unseen disturbances.

Related Reading: Best New Scuba Gear May 2024

Taking it to the Extreme

Exploration often requires traversing challenging environments. From the Antarctic tundra to the black depths of the ocean, Ball Watch has designed their timepieces to withstand some of the most demanding conditions known to man.

Oil is used to lubricate mechanical watch movements. It is necessary to reduce friction between the contact surfaces to prevent components from wearing out. Certain models use specially blended Swiss watch oils that enable them to operate in temperatures ranging from -40 to 140 degrees Fahrenheit (-40 to 60 degrees Celsius).

Underwater exploration exposes timepieces to water and extreme pressure—divers will remember from their certification course that every 33 feet (10 meters) is the equivalent of an entire atmosphere of pressure. Ball Watch has numerous dive models whose water resistance ranges from 330 feet/100 meters to 1,000 feet/300 meters which are suitable for any recreational dive. One of their heavy-duty divers, the DeepQuest, offers a mind-boggling depth rating of 9,850 feet/3,000 meters.

Birth of a Movement

During his lifetime, Webb C. Ball would utilize other manufacturers’ watch movements, usually American or Swiss in origin, in his timepieces. He would modify and adjust these existing movements to better meet his exacting criteria of accuracy and performance. In 2017, Ball Watch Company honored their founder’s unwavering pursuit of precision with the development of the company’s first in-house movement RRM7309-C (the RR of course, stands for railroad).

Precise, efficient and reliable, this automatic self-winding movement perfectly embodies Webb C. Ball’s guiding principles. The movement was COSC-certified following rigorous testing by the Swiss Official Chronometer Testing Institute and meets the high standards originally set by Webb C. Ball himself. The automatic self-winding movement has an 80-hour power reserve. The movement maintains a frequency of 28,000 beats per hour for extreme accuracy. Since its inception, additional variations to RRM7309-C have been developed which include features like a GMT for tracking dual time zones and a silicone balance spring for increased resistance to magnetism and corrosion.

The original Ball Skindiver diver watch

Ball Dive Watches

Though Ball Watch built its reputation primarily through its railroad watches, it did produce other timepieces during its early years. During the mid 20th century, the popularity of scuba diving was quickly growing in the United States. Following the foundation of the Underwater Society of America in 1959, Ball Watch endeavored to create its first diver’s watch which was called the Skindiver.

The Skindiver made its debut in the 1960s, while the mechanical watch industry was in freefall and was very short-lived. In 2010, Ball Watch released a modern reissue of the Skindiver based on the original’s design. Not only did this reinterpretation see a classic timepiece reintroduced, but it became the foundation of Ball's modern dive collection. Below are a few contemporary models that exemplify the brand’s current dive lineup.

The Engineer Master II Diver Chronometer

Featuring a refined size for enhanced everyday wear, this elegant 42-mm diver is depth-rated to 1,000 feet/300 meters. It uses Ball’s RR1101-C COSC-certified movement. The precision movement is surrounded by a mu-metal shield for antimagnetic protection of 1,000 Gauss/80,000A/m. It is also safeguarded by Ball’s Amortiser system, which absorbs external shocks in the event of harsh impacts.

The watch has a bi-directional inner bezel to track dive time operated by the crown at the 2 o’clock position. The bezel can be fully operated underwater. This model marks the first time Ball’s Micro Gas Tubes were placed underneath the bezel.

Additionally, the luminous markers are available in either a classic green and yellow configuration or in a rainbow-colored combination. The dial features a magnified date window and is available in blue or black. The case can be outfitted with either a matching bracelet or rubber strap. This sophisticated dive-ready timepiece is a no-nonsense tool watch with an air of elegance.

Engineer M Skindiver III Beyond

The latest generation of Skindiver, this dive watch delivers a classic design with top-of-the-line craftsmanship. It is depth-rated to 1000 feet/300 meters and utilizes Ball’s RRM7309-C automatic movement with an 80-hour power reserve. It is equipped with the Amortiser anti-shock system for extreme reliability. 35 micro gas tubes on the bezel, hour, minute and second hands allow for precise reading even in absolute darkness.

The uncluttered blue dial and matching bezel are both protected by sapphire crystal. The date window at the three o’clock position includes a magnifier window for enhanced visibility. The 41.5-millimeter stainless case is available with a stainless bracelet with a folding buckle or with a black rubber strap. The caseback features an embossed image of a scuba diver. Rugged good looks and even more rugged components makes this watch right at home whether navigating board rooms meetings and sunken shipwrecks.

Engineer Hydrocarbon NEDU

Engineer Hydrocarbon NEDU

Part of Ball Watch’s Engineer Hydrocarbon line, this beefy dive watch was dedicated to the Navy Experimental Diving Unit, the United States Navy unit responsible for developing operational diving and decompression protocols for the US Armed Forces. This watch is especially noteworthy as this was the model on which Ball Watch debuted the world’s first crown-integrated helium escape valve. The 42-mm case is made of Grade 5 titanium and sports a ceramic luminous unidirectional rotating bezel. It is depth-rated to 2,000 feet/600 meters and is shock-rated for up to 7,500Gs.

In addition to the integrated helium valve, the screw-down crown also includes an innovative crown protection system which guards the crown from damage and ensures the crown in secured and leak-free prior to diving. The dial is available in blue or black and includes a day/date window at the three o’clock position.

The NEDU’s chronometer/stopwatch function can measure up to 12 hours of elapsed time and is fully operable underwater. The watch comes with a tapered titanium and stainless-steel bracelet with a patented folding buckle and extension system for easy wear over dive exposure suits. The watch uses Ball’s original COSC-certified automatic movement. The dial and bezel sport a total of 21 self-powered micro gas tubes for legibility in complete darkness. This technologically advanced, heavy-duty tool watch will impress even the most demanding divers.

Engineer Hydrocarbon DeepQUEST Ceramic

Another heavy-duty, deep-water Hydrocarbon diver, the DeepQuest is undeniably tough. The 42-mm case is made of a single block of solid titanium. Titanium offers superior resistance to scratches, shocks and corrosion—an especially pertinent measure for tools used in marine environments. The monoblock design minimizes structural weak points for greater strength and durability. It is depth-rated to a depth of 3,300 feet/1,000 meters.

The helium-escape valve—a must for deep saturation dives—is seamlessly integrated into the strengthened screw-down crown. The dial includes a date window and is available in black or dark green. The matching unidirectional rotating timing bezel is made of scratch-proof, UV-resistant ceramic. It includes a tapered stainless steel and titanium bracelet with a built-in extension for easy wear over a diving suit.

The watch has a clean streamlined design for clear reading of the indices. Self-powered Micro Gas Tubes markers ensure legibility even in the darkest depths. This heavy-duty diver uses Ball’s RR1101-C automatic movement and has guaranteed shock resistance up to 7,500Gs and an antimagnetic endurance up to 4,800A/m.

With a history now spanning three centuries, Ball Watch Company’s exceptional timepieces continue to offer the same reliability and accuracy that the brand was built on. Those equipped with a Ball watch can rest assured of the quality and commitment behind each timepiece. New advancements from the company continue to push the boundaries of the endurance and precision of mechanical timepieces with innovative technical capabilities and a timeless sense of design and style. No wonder more and more divers are looking “to be on the Ball.”